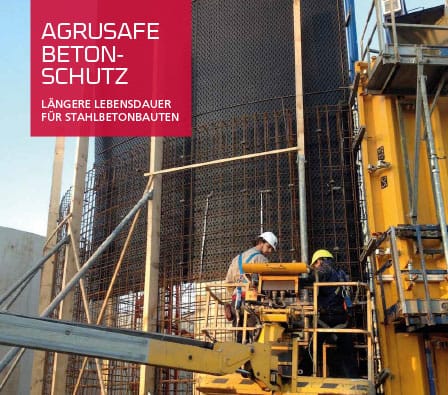

CONCRETE PROTECTION

Safe transportation of aggressive media in industrial applications with robust plastic solutions

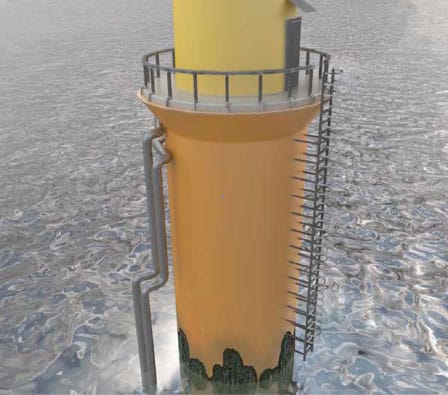

The main focus here is on protecting concrete against environmental influences and aggressive or abrasive media, in order to improve the service life of concrete works.

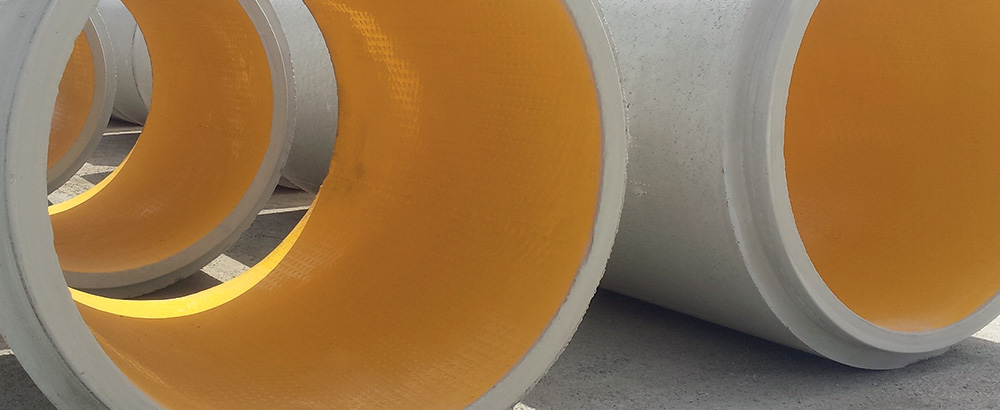

Concrete protective liners are used wherever a concrete building faces tougher requirements. The main applications for concrete protective liners are, in particular, in transportation and storage of liquids, and where chemical resistance cannot be ignored.

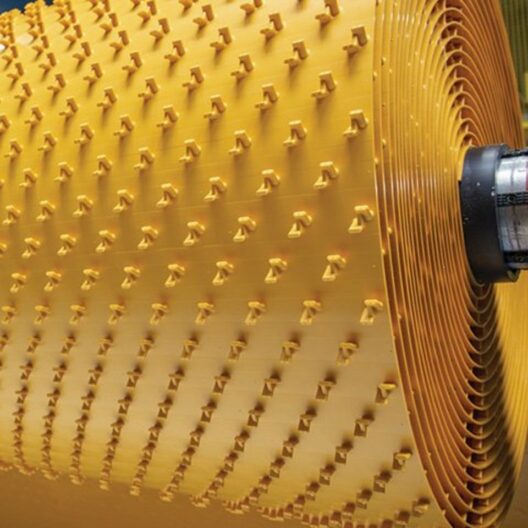

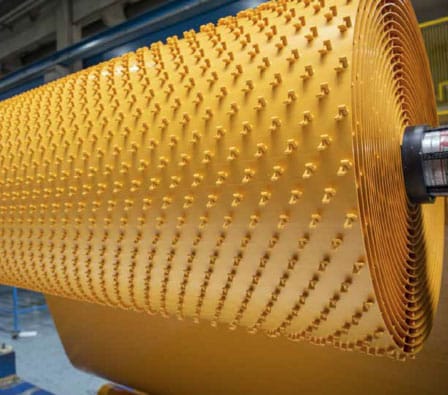

Effective protection for concrete is ensured by the combination of the benefits of special thermoplastic liners (flexible, ductile, no corrosion) with those of concrete (high strength, high stiffness). The concrete is effectively protected therefore prolonging the service life of the structures. Concrete protective liners are therefore a useful option in many concrete building applications, in renovation work, for example. Absolute mechanical anchoring and bridging of cracks in concrete, as well as excellent shear and impact strength and the durability of the liners for concrete protection are just a few of the many benefits.

Concrete protective liners are welded together to create permanent and reliable joints. Depending on the project requirements, butt welding, extrusion and hot wedge welding are necessary for a reliable and leak tight weld, which additionally offers chemical resistance.