LINING SYSTEMS

Sustainable production of plastic sealing membranes at AGRU: 30 years of quality and environmental protection

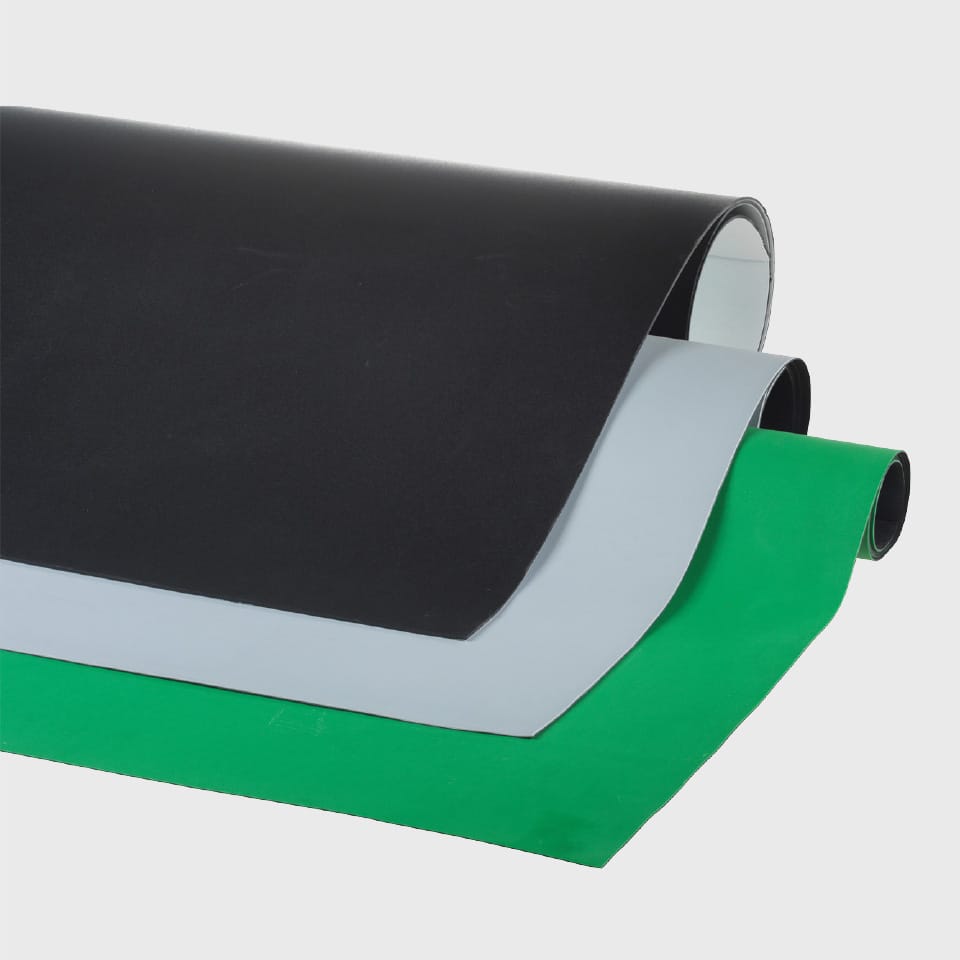

At AGRU we have been producing plastic liners by means of flat-die film extrusion with a downstream calender to the highest quality standards for more than 30 years. Our Lining Systems product group offers a comprehensive range of plastic liners made of HDPE, FPP and FPO. The versatility and quality of the materials we use means that we can tailor solutions to meet customer needs in cooperation with the customer.

The use of quality materials in combination with state-of-the-art production equipment helps us to achieve premium product quality. External audits by recognised test bodies at regular intervals demonstrate our compliance with required standards. This is documented in the form of several approvals. In addition to our head office in Bad Hall (Austria) we also manufacture liners at our plants in Georgetown (South Carolina, USA) and Reno (Nevada, USA).

At AGRU we have taken the concept of ecological thinking one step further to make our production a little bit “greener”. In 2011, our entire liner production was relocated to a separate building where we implement a number of measures for sustainable production. Besides a heat recovery system, geothermal energy probes, a photovoltaic system and wood chip heating contribute towards environmental production of our liners.

In our production of premium quality liners, drain pipes and accessories, AGRU makes a decisive contribution to groundwater protection and ensures a safe water supply. On top of this, AGRU’s AGRUFLEX tunnel liners ensure our daily mobility, AGRUFLEX pond liners and RELAX pool liners guarantee bathing fun.